Reveiving Incoming Repairs

- Visual inspection of all inbound modules (any additional parts, fire damage, breakages etc. are documented).

- Photograph of goods for complete documentation.

- Part Number and serial number are scanned.

- Unit logged in our system and given a repair reference number.

Cleaning & Ultrasonic Baths

- Unit is disassembled and is cleaning with special environmentally friendly cleaning agent.

- Cleaning of module is done before each repair.

- If required, the repairable unit is deep-cleaned using industrial ultrasound cleaning process.

- Certain modules also require conformal coating removal.

Drying Process

- To eliminate chances of short circuit, the repairable module is dried in the drying chamber.

Pre-Repair Test

- Performed to analyze fault pattern.

- Comparison with database of faults and customer's fault/problem description.

Diagnosis & Repair aids

Repairable Unit put through precise fault analysis with the latest testing gadgets and test systems

Our line of cutting-edge testing devices and diagnostic systems, help our repair team(s) to precisely locate, pinpoint faults and resolve them.

- We perform diagnostic tests and repairs with the latest equipment.

- For details please see our "Diagnostics" section.

DIAGNOSTIC DEVICES AND TOOLS

Thermal Imaging Camera and Oscilloscope

Thermal imaging cameras, that have been specifically developed to find faults in electric systems and electromechanical devices, are used for the purpose of even faster and more efficient fault detection. These cameras help our technicians to detect thermal weak points in electronic modules while working in our in-house repair workshop as well as when working at the customer's site.

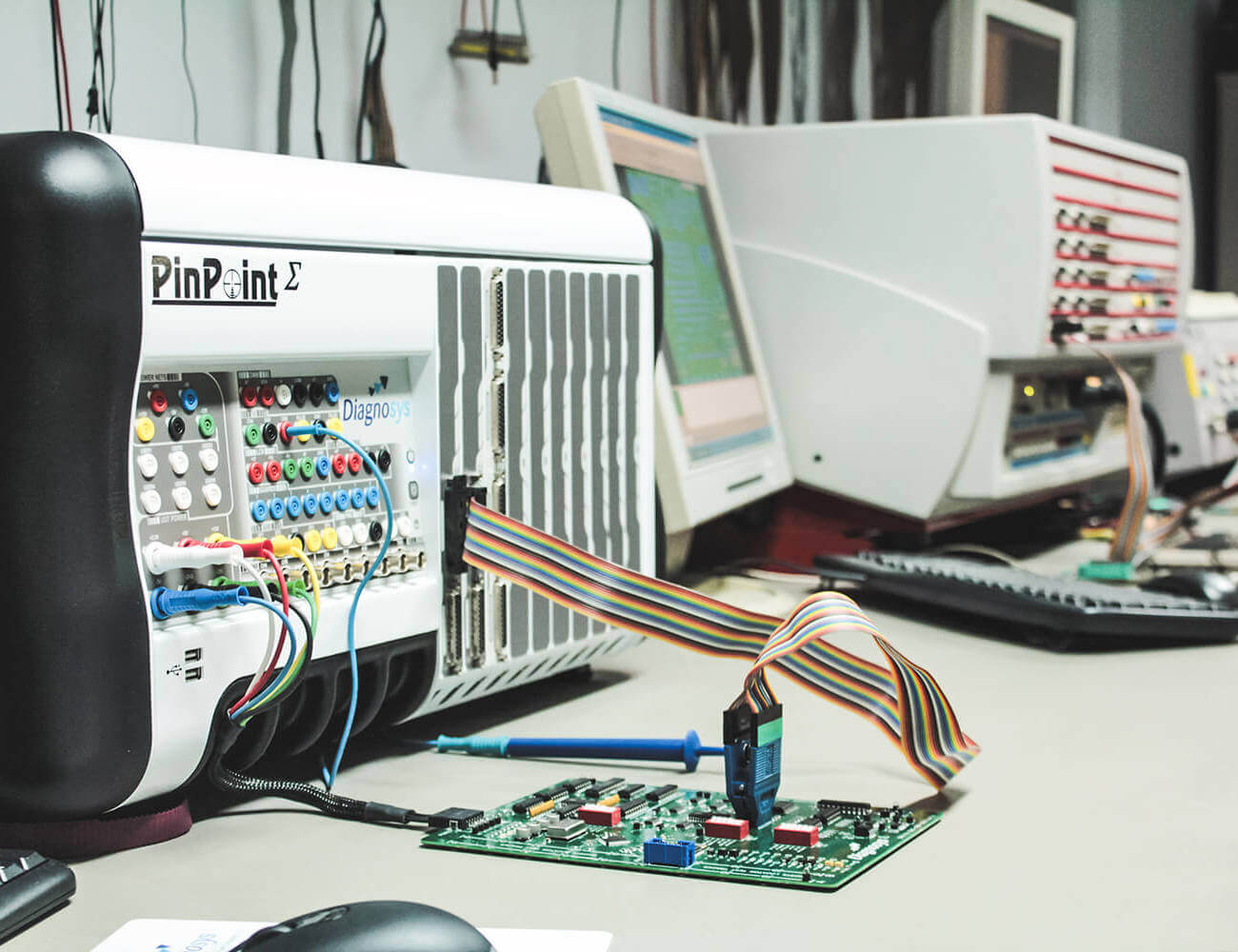

Logic Tester

The compact and flexible InCircuit/function test system can be used to locate faults on digital and hybrid-equipped circuit boards. The function of the individual ICs is tested with test clips. The use of PinPoint diagnostic technology ensures a fast and efficient fault analysis is completed and its excellent fault detection rate means that it is particularly reliably for intense testing phases and sporadic errors.

Rework Station

By using the rework station, it is possible to unsolder ball grid arrays (BGAs) from modules, to reball them or to replace them with new BGAs and resolder them as part of a semi-automated process. The system ensures that all of the neighbouring components are exposed to minimal thermal loads during the unsoldering and soldering process. As the process is semi-automated, it can be repeated with complete accuracy if it has been programmed.

The integrated Dip&Print station ensures that the optimum amount of flux paste is applied to the BGA providing an excellent soldering result and minimal contamination.

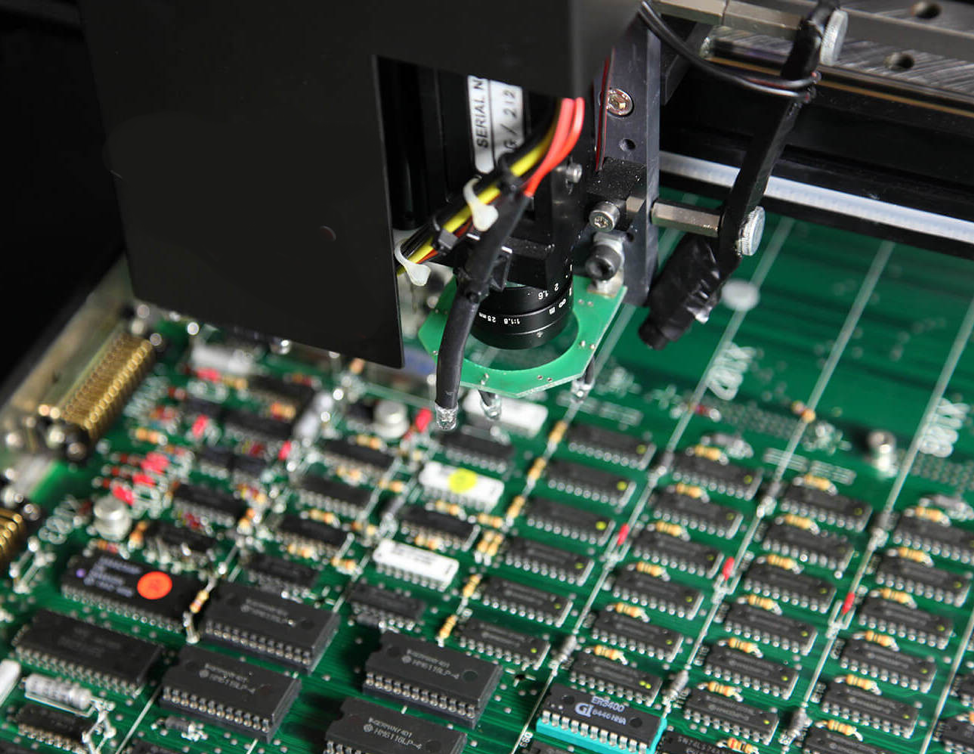

Flying Prober

Hands free and adapter free continuous test system is used to find production faults on circuit boards and the repairs get expedited. The fully automated prober approaches the X/Y/Z-controlled testing probe at the specified test points at high speed ensuring that open lines, short circuits and component failure faults can be identified clearly.

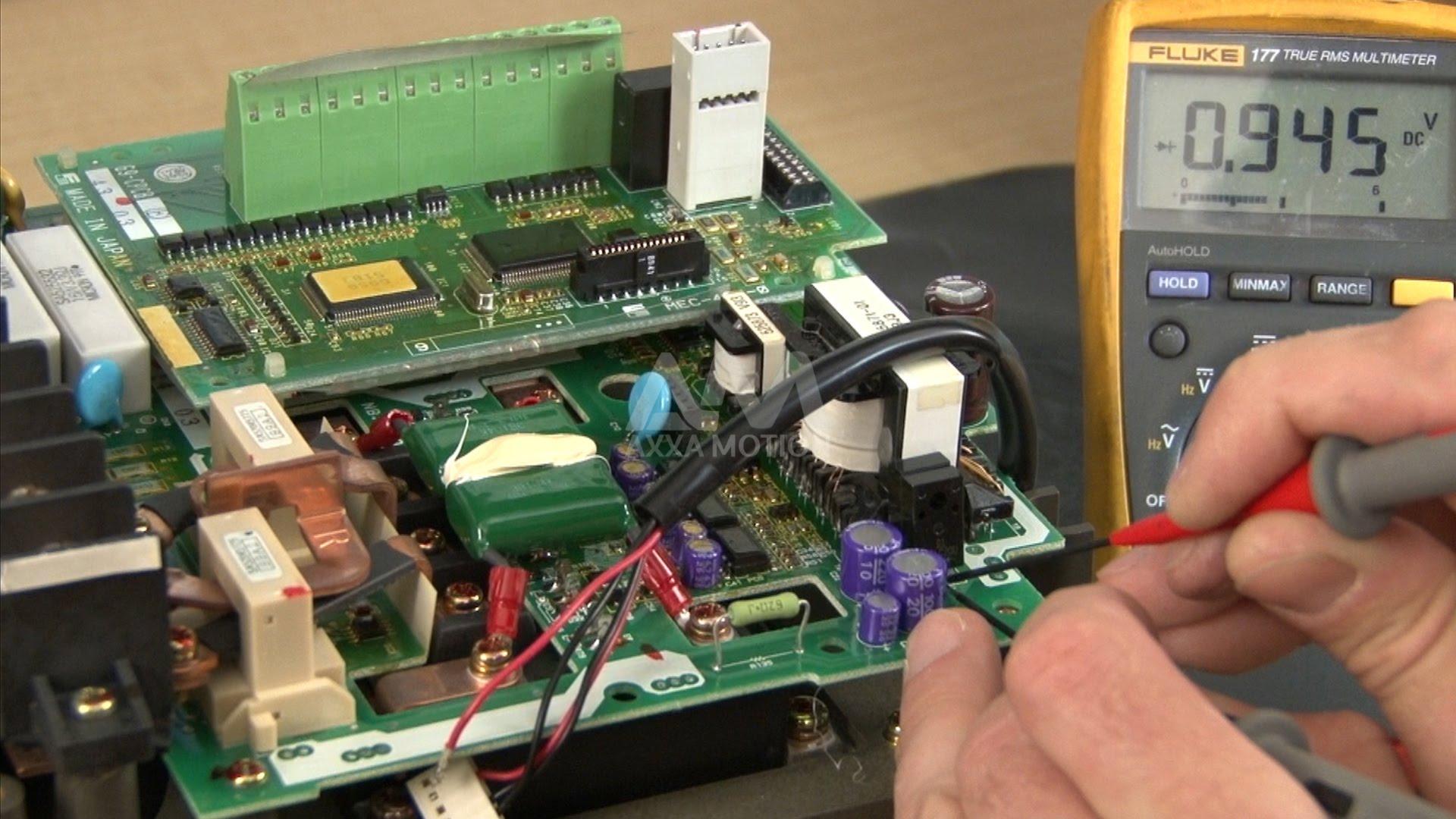

VI measurement instrument

Axxa offer a full range of testing services covering in-circuit test (ATE), functional and full system testing of your electronic products and assemblies. We place a high priority on test and measurement to ensure product reliability.

Huntron VI measurement trackers are used to test and diagnose faulty components by measuring in-circuit signatures. Three dimensional scans of the components are captured during this process so that a snapshot of the current/voltage characteristic can be determined at a fixed frequency.

A three-dimensional characteristic curve is also recorded with a variable frequency as the Z-axis. The measurement instrument thus enables integrated circuits (IC) to be measured virtually, creating a pin-to-pin measurement at the same time. Frequency-dependent components are thus scanned across a large range and an IC can be recorded in all variables within seconds. All of the characteristic curves are saved during this process and can be called up again for subsequent test sequences.

For quality assurance, test flows are programmed for the modules so that consistent quality can be guaranteed when troubleshooting and resolving faults.

Programmer

The Prommer enables us to program more than 110,000 devices (Proms, EProms, EEproms, flash, NAND flash, etc.) from more than 350 plus manufacturers. The Prommer enables to implement in-circuit programming via the integrated ISP adapter.

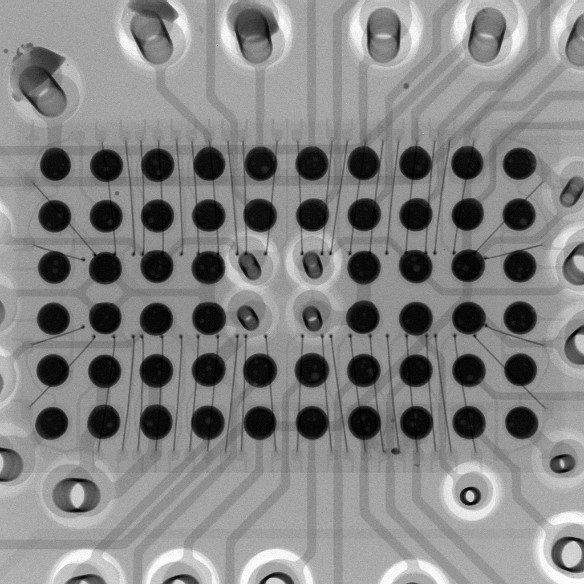

X-Ray Machine

The contemporary electronics is a continuing steady trend towards smaller, more densely populated printed circuit board assemblies (PCBAs). New designs are using significantly more ball grid array (BGA) and other types of devices with hidden solder connections, such as quad flat no-leads (QFN) and land grid arrays (LGAs). Such devices often have performance and cost advantages over larger packages with leads, so the trend is likely to continue.Using X-ray as an in-process control helps to remove the risk of producing assemblies that are impossible or uneconomical to repair due to misplaced ‘hidden connection’ devices. Reworking a misplaced device is time consuming and may cause other issues on the assembly, for example with surrounding components on the PCB due to local heating. X-ray allows inspection without resorting to potentially destructive re-work or micro sectioning

The contemporary electronics is a continuing steady trend towards smaller, more densely populated printed circuit board assemblies (PCBAs). New designs are using significantly more ball grid array (BGA) and other types of devices with hidden solder connections, such as quad flat no-leads (QFN) and land grid arrays (LGAs). Such devices often have performance and cost advantages over larger packages with leads, so the trend is likely to continue.Using X-ray as an in-process control helps to remove the risk of producing assemblies that are impossible or uneconomical to repair due to misplaced ‘hidden connection’ devices. Reworking a misplaced device is time consuming and may cause other issues on the assembly, for example with surrounding components on the PCB due to local heating. X-ray allows inspection without resorting to potentially destructive re-work or micro sectioning

Our repair lab is equipped with a modern X-Ray equipment and visual aids that can magnify up to 2000X; easily detecting any shorts circuit or voids.

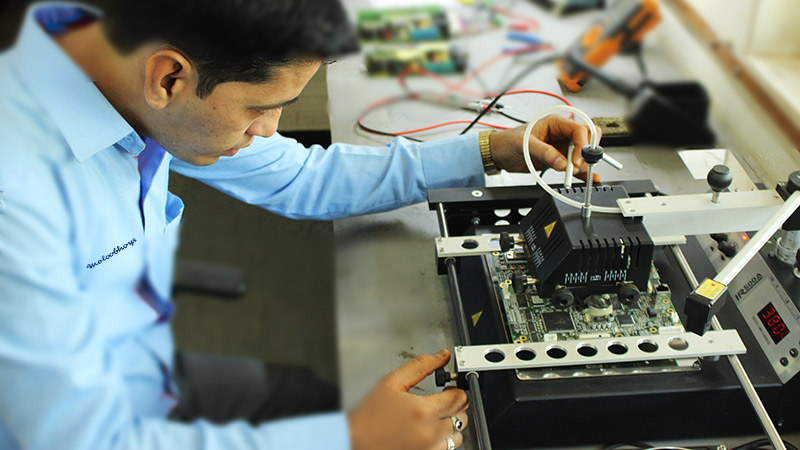

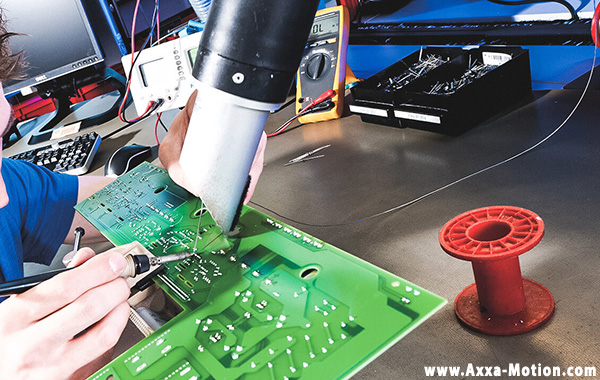

Repair Work

Axxa provides rapid and cost-effective rework solutions for numerous electronic OEMs and for the end users. Our engineering lab is fully equipped with numerous BGA rework systems operated by highly trained technical teams.

- Replacement of defective components.

- Use of quality components for repairs.

- Repair and exchange of obsolete/legacy modules.

Contact Us or call us at (716) 270-0047 or your industrial automation controls repair and purchase needs.